Factory Long Carbide Corner Radius Milling CNC Machine Cutting Tool

Overview Package Size 35.00cm * 18.00cm * 15.00cm Package Gross Weight 5.000kg Product Description RLD Factory directly

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | long carbide corner radius end mills |

| Material | Solid Carbide |

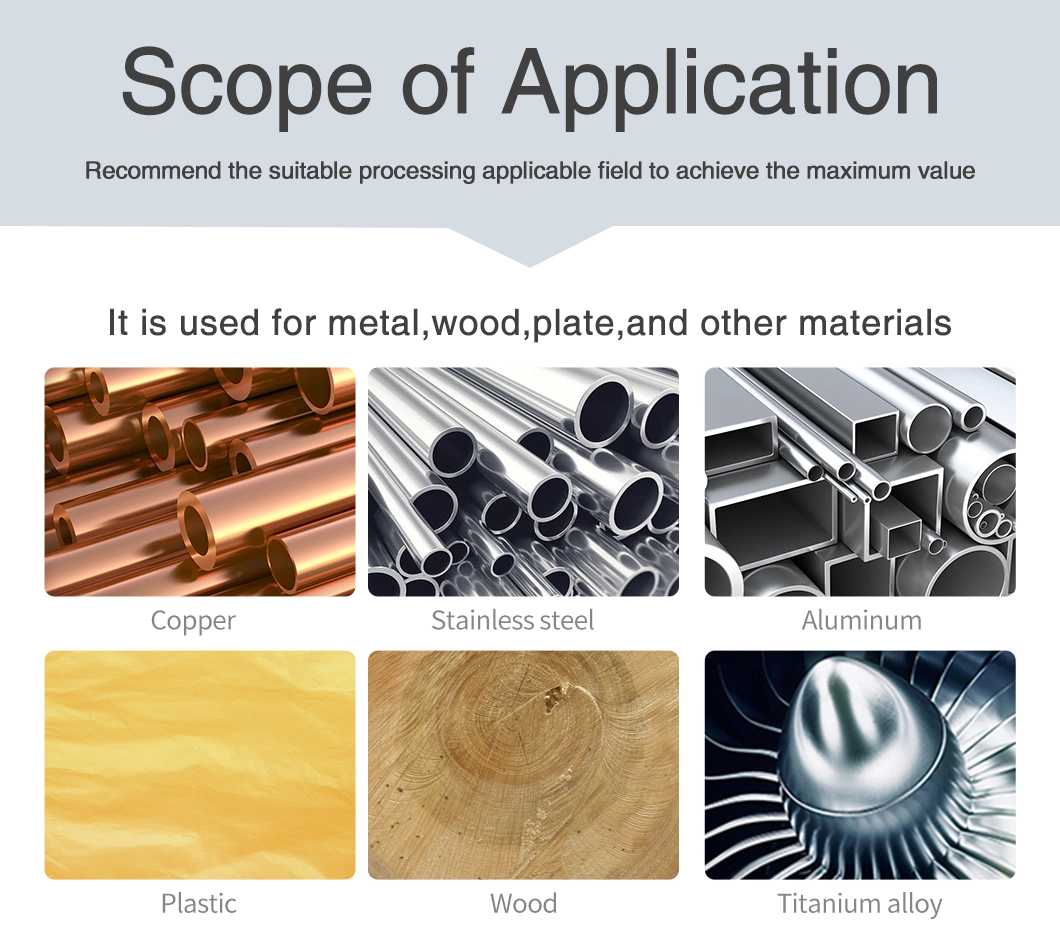

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| HRC | 58 |

| Bending Strength | >=4200 |

| Movement Method | Contour Control |

| Finish Surface | Plain Surface, The Side, Socket |

| Helix Angle | 35 Degree |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Flute | 4f |

| Free Service | OEM |

| Suitable for | Copper, Cast Iron, Carbon Steel, Mould Steel |

| Transport Package | 1PC in a Plastic Tube, 10PCS a Group |

| Trademark | Hiboo |

| Origin | Changzhou Jiangsu China |

| HS Code | 8207709000 |

| Production Capacity | 50000PCS/Month |

Packaging & Delivery

Package Size 35.00cm * 18.00cm * 15.00cm Package Gross Weight 5.000kgProduct Description

Product Description

RLD Factory directly CNC HRC55 solid carbide corner radius end mills milling cutter 4 flutes for cutting metal steel

Product Name | RLD Factory directly CNC HRC55 solid carbide corner radius end mills milling cutter 4 flutes for cutting metal steel |

| Features | Top-rated Series |

| Processing Type | Metal |

| Precision | within 0 ~-0.01mm |

| HRC | 55 |

| Suitable For | Iron, Cast iron, Common steel, Hardened Steel under hardness HRC55 |

| Machine Type | CNC Milling Machine |

| Flutes | 4 |

| Diameter | 1-20mm |

| Overall Length | 50-150mm |

| Co | 12% |

| TRS Min(N/MM²) | 4000 |

| HRA | 92.2 |

1).Super Raw Materails:Kennametal Metal, Sandvik Carbide , CB Carbide from Taiwan

| HRC45 | HRC55 | HRC60 | HRC65 |

| YG10X | YG10.2 &WF25(Taiwan) | K44 & K40 | Sandvik H10F |

| Grain Size:0.7umCo:10 %Flexural strength:3800N/mm2 | Grain Size:0.6umCo:10 %Flexural strength:4000N/mm2 | Grain Size:0.5umCo:12 %Flexural strength:4300N/mm2 | Grain Size:0.4umCo:12.5 %Flexural strength:4300N/mm2 |

2).High Quality TiSiN Coating , get the longer tool life

| AlTiN | TiAIN | TiSiN | Nano | |

| Hardness(HV) | 3200 | 2800 | 3600 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 |

| Oxidation Temp(°) | 900 | 800 | 1000 | 1200 |

| Friction Coeffient | 0.3 | 0.3 | 0.45 | 0.4 |

| Color | Black | Violet | Copper | Blue |

Product Show

Product Specification

The following Specification for your refer, We also provide the OEM or ODM service

| order number | cutting | Flute | Shank | Corner | A.0.L |

| d | l | D | R Corner | L | |

| 1×3×4D×R0.2×50L×4F | 1 | 3 | 4 | R0.2 | 50 |

| 1×3×4D×R0.3×50L×4F | 1 | 3 | 4 | R0.3 | 50 |

| 1.5×3×4D×R0.2×50L×4F | 1.5 | 4 | 4 | R0.2 | 50 |

| 1.5×3×4D×R0.3×50L×4F | 1.5 | 4 | 4 | R0.3 | 50 |

| 2×6×4D×R0.2×50L×4F | 2 | 6 | 4 | R0.2 | 50 |

| 2×6×4D×R0.3×50L×4F | 2 | 6 | 4 | R0.3 | 50 |

| 2.5×8×4D×R0.2×50L×4F | 2.5 | 6 | 4 | R0.2 | 50 |

| 2.5×8×4D×R0.5×50L×4F | 2.5 | 6 | 4 | R0.5 | 50 |

| 3×8×3D×R0.3×50L×4F | 3 | 8 | 3 | R0.3 | 50 |

| 3×8×3D×R0.5×50L×4F | 3 | 8 | 3 | R0.5 | 50 |

| 3×8×4D×R0.3×50L×4F | 3 | 8 | 4 | R0.3 | 50 |

| 3×8×4D×R0.5×50L×4F | 3 | 8 | 4 | R0.5 | 50 |

| 4×10×4D×R0.5×50L×4F | 4 | 10 | 4 | R0.5 | 50 |

| 4×10×4D×R1.0×50L×4F | 4 | 10 | 4 | R1.0 | 50 |

| 4×10×6D×R0.5×50L×4F | 4 | 10 | 6 | R0.5 | 50 |

| 4×10×6D×R1.0×50L×4F | 4 | 10 | 6 | R1.0 | 50 |

| 5×13×6D×R0.5×50L×4F | 5 | 13 | 6 | R0.5 | 50 |

| 5×13×6D×R1.0×50L×4F | 5 | 13 | 6 | R1.0 | 50 |

| 6×15×6D×R0.5×50L×4F | 6 | 15 | 6 | R0.5 | 50 |

| 6×15×6D×R1.0×50L×4F | 6 | 15 | 6 | R1.0 | 50 |

| 8×20×8D×R0.5×60L×4F | 8 | 20 | 8 | R0.5 | 60 |

| 8×20×8D×R1.0×60L×4F | 8 | 20 | 8 | R1.0 | 60 |

| 8×20×8D×R1.5×60L×4F | 8 | 20 | 8 | R1.5 | 60 |

| 10×25×10D×R0.5×75L×4F | 10 | 25 | 10 | R0.5 | 75 |

| 10×25×10D×R1.0×75L×4F | 10 | 25 | 10 | R1.0 | 75 |

| 10×25×10D×R1.5×75L×4F | 10 | 25 | 10 | R1.5 | 75 |

| 10×25×10D×R2.0×75L×4F | 10 | 25 | 10 | R2.0 | 75 |

| 12×30×12D×R0.5×75L×4F | 12 | 30 | 12 | R0.5 | 75 |

| 12×30×12D×R1.0×75L×4F | 12 | 30 | 12 | R1.0 | 75 |

| 12×30×12D×R1.5×75L×4F | 12 | 30 | 12 | R1.5 | 75 |

| 12×30×12D×R2.0×75L×4F | 12 | 30 | 12 | R2.0 | 75 |

| 3×8×3D×R0.3×75L×4F | 3 | 8 | 3 | R0.3 | 75 |

| 3×8×3D×R0.5×75L×4F | 3 | 8 | 3 | R0.5 | 75 |

| 3×8×4D×R0.5×75L×4F | 3 | 8 | 4 | R0.5 | 75 |

| 3×8×4D×R1.0×75L×4F | 3 | 8 | 4 | R1.0 | 75 |

| 4×10×4D×R0.5×75L×4F | 4 | 10 | 4 | R0.5 | 75 |

| 4×10×4D×R1.0×75L×4F | 4 | 10 | 4 | R1.0 | 75 |

| 4×10×6D×R0.5×75L×4F | 4 | 10 | 6 | R0.5 | 75 |

| 4×10×6D×R1.0×75L×4F | 4 | 10 | 6 | R1.0 | 75 |

| 5×13×6D×R0.5×75L×4F | 5 | 13 | 6 | R0.5 | 75 |

| 5×13×6D×R1.0×75L×4F | 5 | 13 | 6 | R1.0 | 75 |

| 6×15×6D×R0.5×75L×4F | 6 | 15 | 6 | R0.5 | 75 |

| 6×15×6D×R1.0×75L×4F | 6 | 15 | 6 | R1.0 | 75 |

| 8×20×8D×R0.5×100L×4F | 8 | 20 | 8 | R0.5 | 100 |

| 8×20×8D×R1.0×100L×4F | 8 | 20 | 8 | R1.0 | 100 |

| 8×20×8D×R1.5×100L×4F | 8 | 20 | 8 | R1.5 | 100 |

| 10×25×10D×R0.5×100L×4F | 10 | 25 | 10 | R0.5 | 100 |

| 10×25×10D×R1.0×100L×4F | 10 | 25 | 10 | R1.0 | 100 |

| 10×25×10D×R1.5×100L×4F | 10 | 25 | 10 | R1.5 | 100 |

| 10×25×10D×R2.0×100L×4F | 10 | 25 | 10 | R2.0 | 100 |

| 12×30×12D×R0.5×100L×4F | 12 | 30 | 12 | R0.5 | 100 |

| 12×30×12D×R1.0×100L×4F | 12 | 30 | 12 | R1.0 | 100 |

| 12×30×12D×R1.5×100L×4F | 12 | 30 | 12 | R1.5 | 100 |

| 12×30×12D×R2.0×100L×4F | 12 | 30 | 12 | R2.0 | 100 |

Packaging & Shipping

Package and shipping details

Laser brand on the cutter's shank , 1 pc in a plastic tube , 10pcs a group

We cooperated with DHL , Fedex, UPS ,TNT, EMS and other express you wanted.

Delivery Time

For samples , we dispatch your tools in 2-7 workdays .

For formal orders,We delivery tools to you in 7-30 workdays , it will depond on your order quantity.Payment Term

T/T ,Western Union , MoneyGram,L/C

Company Profile

Changzhou Hiboo Tools Co., Ltd is a high-tech enterprise with all vitality, potential and comprehensive Strength. The company located in Changzhou, Jiangsu, China, a unique place near by Shanghai.We are Gold Supplier who specialized in producting and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.The efficient workshop and Imported 5AXIS grind machines run by skillful operators. The strict inspection standards to make sure each cutter is inspected by Zoller Measuring and Inspecting Machine. Now, Our monthly output up to 50000pcs of carbide end mills, drills ect, More than 20000 cutters are in stock which meet your urgent requirements. Enough Raw Materials in stock to keep the price stability.Exhibition Events